If you’ve spent the last few weeks or months polishing a batch of rocks it can be extremely disappointing if they come out looking dull or hazy. The first batch of rocks my daughter and I tumbled together didn’t quite live up to our expectations, but we have since refined the process and now we reliably end up with great results. If your rocks didn’t end up as shiny as you’d like, here are the likely reasons why and how to fix them.

Tumbled rocks may not be shiny for the following reasons:

- Unsuitable tumbling rough

- Improper cleaning between stages

- Inferior grit or polishing compounds

- Misuse or lack of tumbling media

- Rushing the tumbling process

- Rocks need a burnishing step

Any one of these reasons is enough to result in a subpar finished product. It can feel like a huge waste of time and money if your rocks come out with anything less than a mirror-like shine. But don’t despair, the problem is fixable! I’ll dive deeper into why each of these mistakes creates poor results and, more importantly, how to avoid and fix them.

Reasons Why Tumbled Rocks Aren’t Shiny (And How to Fix Them)

If your rocks aren’t as shiny as you’d like them at the end of the tumbling process, don’t lose hope. With a little more time and effort it’s very likely that you can still achieve the high level of polish you were hoping for, and at the very least by reading this article you’ll learn how to avoid disappointing results in the future. Here are the most likely reasons your rocks aren’t shiny and how to correct them.

| Reason | Correction |

|---|---|

| Unsuitable tumbling rough | Only tumble hard, high-quality rocks |

| Improper cleaning between steps | Thoroughly clean rocks and barrel between steps |

| Inferior grit or polish | Use high-quality, appropriate grit & polish sizes |

| Misuse or lack of tumbling media | Use correct types and amounts of tumbling media |

| Rushing the tumbling process | Take as much time as needed, don’t rush |

| Rocks need to be burnished | Add a burnishing step after the polishing phase |

Unsuitable Tumbling Rough

Tumbling rocks that aren’t suitable to go into a rock tumbler is one of the most common reasons for poor results. I have previously covered the topic of what makes for good tumbling rough, but I’ll briefly touch on the topic here as well.

Article: Best Rocks for Tumbling: Why Some Work & Others Don’t

There are four characteristics that every one of your rocks must meet in order to produce a good polish on your batch. If even one of them doesn’t meet any of these requirements it can and will spoil the polish on the rest of your rocks. Have high standards when it comes to choosing which rocks you’ll allow into your tumbler’s barrel, otherwise you may end up wasting a lot of time and money.

All of the rocks you place in your tumbling barrel must:

- Be of similar hardness – Most rocks you’ll tumble will be between a 6 and 8 on the Mohs hardness scale. Most importantly, all of your rocks should be of similar hardness, not deviating more than 1.5 or 2 on the hardness scale from one another. Otherwise, the harder rocks will ‘eat’ the softer ones. Remove any overly hard or soft rocks from your tumbling barrel and save them to be tumbling later with rocks of similar hardness.

- Have a smooth texture – If any of your rocks have a gritty or sandy texture then they are not suitable for tumbling. The rocks should be microcrystalline, without any visible grains. If you rub them together, they should not produce any sand-like particles. Rocks like this break down and their gritty remnants will scratch your other rocks. Remove any rocks with this texture from your tumbling barrel.

- Have no fractures – A rock with noticeable fractures has the potential to trap grit and transport it between tumbling stages. This leftover grit has the potential to become dislodged in the polishing stage and scratch up the surface of the rocks you’re trying to polish. Remove any rocks with fractures before the polishing stage. You can break them along the fracture and re-tumble them in another batch.

- Be of appropriate size – Tumbling rough should generally be composed of a good mix of rocks between 1/2″ and 1-1/2″ in size. Anything larger will tend to interfere with proper tumbling action, and anything smaller may end up being completely destroyed in the tumbling process. A good mix helps ensure good distribution of tumbling grit and promotes proper grinding action.

Again, if any of your rocks don’t meet these qualifications they should be discarded. In many cases, you can save them to be tumbled in another batch. Don’t get greedy by trying to move every single rock along to the next stage of the tumbling process. It’s better to be selective and patient than to risk ruining an entire batch just for the sake of one or two more rocks. Not all rocks are ready to be moved along in the process at the same time, so it’s okay to hold a few back.

Look at the rocks you just pulled out of your polishing stage. If any of them have cracks, holes, a gritty texture, or you know they’re harder than the rest of the rocks, remove them. Then re-run the rest of your rocks in the pre-polish and polishing steps and you will very likely see much-improved results.

Improper Cleaning Between Steps

A lack of thorough cleaning is undoubtedly the biggest culprit when it comes to poor rock tumbling results. It can be very tempting to just rinse off the entire batch and the inside of the tumbling barrel and call it good, but that is almost never enough when it comes to cleaning between steps.

You have to make sure that the barrel and the rocks are completely cleaned off and there is no grit or slurry from the previous stages left anywhere. This is especially important in the pre-polish and polishing steps, when any little bits of coarser grit will scuff up the surface of your rocks and ruin the desired effect.

I like to use a kid’s toothbrush to reach the edges of the tumbling barrel. It’s also a very good idea to wash and inspect every rock individually and not to rely on rinsing them all at once. As you do this, scrub them off and inspect them for signs of cracking or any new holes where old slurry could be hiding. If you find any of these, remove that rock and re-run it in that stage with a later batch.

If you suspect that improper cleaning is the culprit with your batch of rocks, try thoroughly rinsing the entire batch and re-running it in the pre-polish and polish stages. The additional time spent in an environment completely devoid of coarser grit will likely lead to significant improvement in their appearance.

Inferior Grit or Polishing Compounds

This is a big problem for beginners, through no real fault of their own. Many tumblers come with a beginner’s batch of rocks and enough grit to run them through the entire tumbling process. However, the grit that comes with these tumblers is notoriously poor in quality – especially when it comes to the pre-polish and polish.

The National Geographic Tumbler (which I personally recommend) and the Lortone introductory kits are both guilty of this. You can get decent results using their grits if you do everything else right, but nothing like you’d accomplish with proper grit and polish.

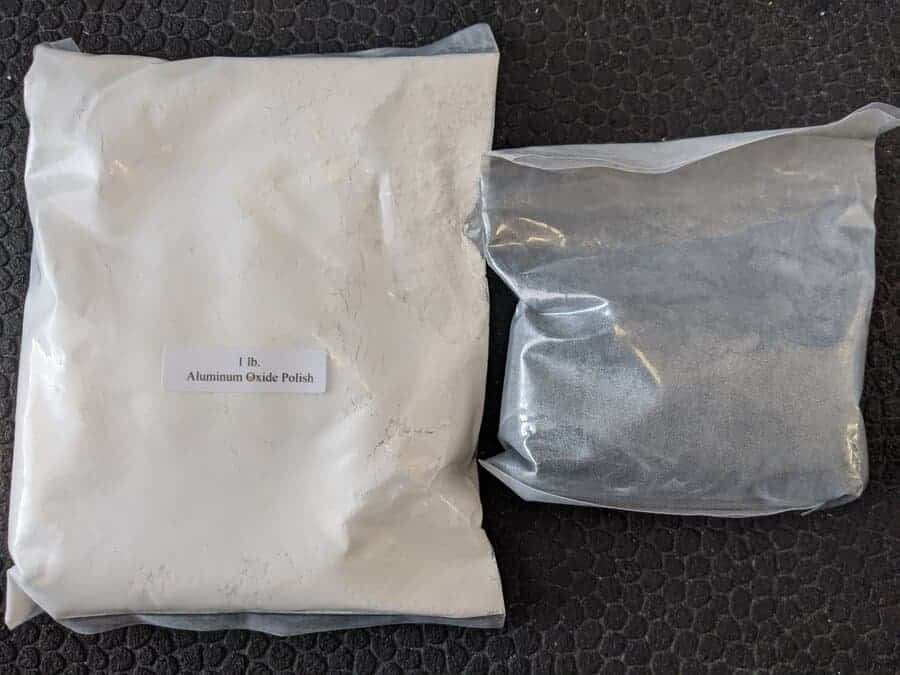

As a general rule of thumb, you should always buy high-quality grit from a trusted source. If your ‘polish’ is black, then it’s not proper polish at all. I would recommend using this tumbling grit and polish from The Rock Shed (link to Amazon) which includes proper aluminum oxide polish. Real polish will look like extremely fine powdered sugar.

If you used a ‘polish’ that wasn’t really a proper polish, I would again recommend that you just re-run your batch of rocks with higher quality materials. You should start from at least the pre-polish stage, and maybe even consider going back to ‘step 2’ of the tumbling process for best results.

Misuse or Lack of Tumbling Media

As you progress in the tumbling process you will likely need to use some sort of tumbling media. I have previous written extensively about the different types of tumbling media and their uses but I will cover it briefly here as well.

Tumbling media serves several purposes in the barrel. It helps fill the barrel to the proper level (about 2/3 to 3/4 full) which promotes good tumbling action. This will become more important as you lose rock volume over time to the grinding action and remove problematic rocks from the tumbler between steps.

Tumbling media also helps fill the void space between the rocks and increases the number of contact points where grinding action can occur. More importantly in the polishing step, tumbling media provides some cushioning for the rocks so that they don’t fall too far or too quickly in the barrel. This prevents them from cracking or rubbing too hard against one another. In the polishing step, you want nice smooth contacts with no hard impacts.

If you haven’t used any tumbling media to this point, it is very likely worth your while to go back to at least the pre-polish step and add some tumbling media. While I personally prefer to use ceramic tumbling media like this (link to Amazon) if you are having a lot of trouble getting a good polish I would probably recommend trying plastic pellets (link to Amazon). These plastic pellets provide a lot of cushioning for the rocks in the barrel and will promote a nice smooth ride during the polishing step.

Rushing the Tumbling Process

Another mistake that many tumbling enthusiasts often fall into is rushing the process. Rock tumbling is not a hobby for the impatient. As a general rule, you should err on the side of letting your rocks go for too long in each stage than not long enough. If you move rocks along in the process too quickly you will likely end up with irregular shapes and rocks that haven’t been ground down enough.

The shaping of the rocks happens primarily in the first and second steps of tumbling, but those steps also set the stage for a good polish. Make sure that the rocks have had long enough to wear away any irregularities, voids, and cracks that may trap grit and make it difficult for the polish to do its work.

The hardness of your rocks will have a huge impact on how long each stage should take. Harder rocks (hardness of 7 or more) will likely require more time in each stage to get desired results. Have patience and know that the time spent will be worth it!

If you suspect that you haven’t been patient enough in your process I would recommend going back to step 2. This will allow the rocks to acquire a little better rounded shape. Monitor their progress and only move them along to the pre-polish step if they look ready.

Rocks Need a Burnishing Step

Sometimes you can have done everything right and still not quite have that perfect mirror shine you’re looking for. Often times this is not because of imperfections in the surface of the rock, but rather a haze or scum left on top of the surface. This can be because of hard water or the polishing slurry drying onto the rocks, making it difficult to remove.

One of the best ways to determine if this is the case is to use a high-powered magnifying glass (link to Amazon) to inspect the surface of your rocks. Take a few of your rocks and closely examine them under the magnifying glass to look for any visible scratches or imperfections. If they look completely smooth even under high magnification then your tumbling process has likely been successful, but you just need to add a burnishing step.

Burnishing is a relatively simple process. I recommend using distilled water so that you avoid the hard water problem. Load the barrel the same way you did for the polishing step with rocks and tumbling media (use media that has been tumbled before). Then add some Borax (link to Amazon) or Ivory bar soap instead of grit or polish. Use about 1 tablespoon if you have a 3-pound tumbling barrel. You only need to run the tumbler for a couple of hours to achieve the desired effect. The Borax will thoroughly clean and polish the rocks to a high mirror shine!

By the way, if you want to learn all you can about rocks and minerals, I would highly recommend subscribing to Rock & Gem Magazine. They have great articles from knowledgeable and respected geologists and gemologists all about rock collecting, faceting, field trip ideas, and projects for kids. It’s a must for any aspiring rockhound!